Indlela yokufaka i-gutter yokwakha isakhiwo sensimbi?

Izinto kanye nesicelo

1. Izinto:

Njengamanje, kunezinto ezintathu ezivame ukusetshenziswa kakhulu zegutter: gutter yeplate yensimbi enogqinsi lwepuleti elingu-3 ~ 6mm, gutter yensimbi engagqwali enogqinsi luka-0.8 ~ 1.2mm kanye nogubhu wensimbi onemibala enogqinsi luka-0.6mm.

2. Isicelo:

Udoti wamapuleti ensimbi kanye nogubhu wensimbi engagqwali ungasetshenziswa kumaphrojekthi amaningi.Phakathi kwazo, i-gutter yensimbi engagqwali ivame ukusetshenziswa ezindaweni ezisogwini nasezindaweni ezinegesi egqwalayo enamandla eduze nomsebenzi;Udoti wamapuleti ombala usetshenziselwa ikakhulukazi udoti wangaphandle wesakhiwo segesi namaphrojekthi anendawo encane yobunjiniyela kanye nepayipi elincane lokudonsa amanzi.Ivamise ukusetjenziswa njengomsele wangaphandle.

Indlela yokuxhumana

★ gutter steel plate

1. Izimo zokufaka:

Ngaphambi kokufakwa kwe-gutter ye-steel plate, kufanele kuhlangatshezwane nalezi zimo ezilandelayo: indikimba eyinhloko yesakhiwo sensimbi (ugongolo kanye nekholomu) ifakiwe futhi yalungiswa, futhi wonke ama-bolts anamandla aphezulu agcine eboshwe.Kuphrojekthi ene-parapet, ikholomu ye-parapet kanye ne-wall beam ehambisanayo ifakiwe futhi yalungiswa.I-gutter yamapuleti ensimbi ibikhona endaweni.Imishini yokushisela esebenza ngogesi kanye nemishini yokushisela isikhona.

2. Ukufakwa:

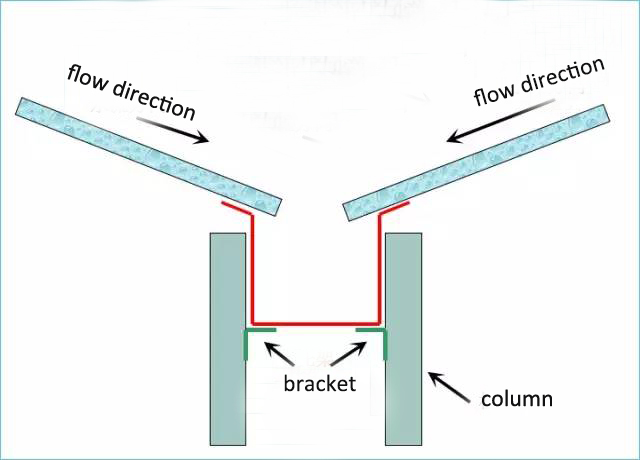

Ngemuva kokuthi i-gutter yensimbi ehambisanayo ihanjiswe endaweni ngokuvumelana nemidwebo yokuklama, i-gutter izothuthelwa endaweni ekhethiwe yokufaka nge-crane noma ngokuthuthwa ngesandla kuye ngobukhulu nesisindo se-gutter, futhi i-gutter izoxhunywa okwesikhashana nge-welding kagesi. ngokushesha.Lapho zonke izinto zikagatha sezimi ngomumo, dweba umugqa ngocingo lwensimbi ngaphandle komsele, bese ulungisa izinhlangothi zangaphakathi nezangaphandle zawo wonke umzila oqondile ofanayo.Ngesikhathi sokulungiswa, qaphela ukunciphisa igebe endaweni ehlangene ye-gutter, futhi uyilungise okwesikhashana nge-welding kagesi.Bese ushisela ngokugcwele i-weld evundlile engezansi kanye ne-weld eqondile nhlangothi zombili ngenduku yokushisela enobubanzi obungu-3.2mm.Ngesikhathi sokushisela, naka ikhwalithi yokushisela futhi ulawule i-welding current, Vimbela ukushisa ngokusebenzisa i-gutter futhi wandise izinkinga ezingadingekile.I-welding yesikhashana ingasetshenziswa ekuxhumaneni phakathi kwe-gutter kanye nangaphezulu kwekholomu.Iphansi le-gutter nangaphezulu kwekholomu yensimbi kungashiswa futhi kulungiswe ukwandisa ukuqina okuphelele.I-gutter engakwazi ukushiselwa ngosuku olufanayo ingalungiswa okwesikhashana nge-welding kagesi ngezindlela ezingenhla.Uma izimo zivuma, igutter ingabuye iboshwe futhi ihlanganiswe ngogongolo olusodongeni noma ubakaki wegutter ngentambo yensimbi.

3. Ukuvulwa kwesitolo:

I-gutter outlet kufanele ibekwe ngokuvumelana nezidingo zokuklama.Ngokuvamile, i-outlet evamile izovulwa ohlangothini lwekholomu yensimbi noma insimbi yensimbi.Naka isikhundla sokusekela lapho uvula imbobo, futhi uzame ukuyigwema ngangokunokwenzeka, ukuze unciphise inani lezesekeli ze-downpipe.Indlela yokufaka ipayipi eliphansi izocatshangelwa ngenkathi kuvulwa.Kungcono ukunquma indlela yokulungisa ye-hoop ye-downpipe kuqala, ukuze unciphise impahla yokulungisa i-hoop futhi unciphise izindleko.Umgodi ungavulwa ngokusika igesi noma i-angle grinder.Kuvinjelwe ngokuphelele ukuvula umgodi ngokuqondile nge-welding kagesi.Ngemuva kokuvulwa komgodi, i-shaft kanye ne-periphery yembobo izocutshungulwa nge-grinder ye-angle, bese kuthi ukuphuma kwamanzi kwepayipi yensimbi kuhlanganiswe ne-gutter.Naka izinga lokushisela ngesikhathi sokushisela ukuze ugweme ukulahleka kwe-welding.Ngemva kokushisela, i-slag yokushisela izohlanzwa ngokuhamba kwesikhathi, futhi insimbi yokushisela ephakeme kakhulu kune-gutter izopholishwa nge-angle grinder ize ibe isicaba.Ukuze uvimbele ukuzima endaweni yokuphuma amanzi, isando singasetshenziswa ukuphihliza indawo yokuphuma amanzi ukuze kube lula ukugeleza kwamanzi.

4. Penda:

Ngemuva kokuthi wonke ama-gutters ahlanganiswe futhi ahlolwe ukuze afaneleke, i-welding slag endaweni yokushisela izohlanzwa ngokuphelele futhi.Ngesikhathi esifanayo, upende endaweni ye-welding kufanele ihlanzwe ngebhulashi lensimbi, bese ilungiswa ngopende lwe-antirust lokucaciswa okufanayo njengopende wokuqala.I-gutter finish izopendiwa ngaphambi kokwakhiwa kwephaneli yophahla ngokuvumelana nezidingo zokuklama.Uma zingekho izidingo zokuklama, olunye ungqimba lwe-neoprene luzopendwe ohlangothini lwangaphakathi lomsele wensimbi ukuze kulungiswe ukubola.

★ ukufakwa kwe-gutter yensimbi engagqwali

1. Izimo zokufakwa kanye nezidingo zokuvula amapayipi aphansi egutter yensimbi engagqwali ziyefana nalezo ze-steel plate gutter.

2. I-Argon arc welding yamukelwa ukushisela i-gutter yensimbi engagqwali, futhi ucingo lwensimbi engagqwali lwento efanayo ne-gutter yamukelwa njengenduku yokushisela, futhi ububanzi bungase bufane nobukhulu bepuleti.Ngokuvamile 1mm.Ngaphambi kokushisela okusemthethweni, ama-welders azohlelwa ukuze aqhube ukushisela, futhi ukushisela i-batch kungaqala kuphela ngemva kokuphumelela ukuhlolwa.Ngesikhathi esifanayo, kungcono ukuqoka izisebenzi ezikhethekile zokushisela, futhi uhlele isisebenzi esisizayo ukuze sisebenzisane nokusebenza, ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza okuyinhloko.Ngemva kokuba indawo yokuphuma amanzi isishiselwe, indawo kufanele futhi iphihlizwe phansi ukuze kube lula ukugeleza kwamanzi.Uma kune-sediment nokunye ukungcola ku-electrode yensimbi engagqwali, kufanele isuswe ngaphambi kokusetshenziswa.

3. Ngenxa yokuthi i-gutter yensimbi engagqwali iyacutshungulwa futhi yakhiwe ngokugoqwa, akunakugwenywa ukuthi kube khona ukuchezuka kwe-dimensional.Ngakho-ke, ngaphambi kokuba i-gutter ihanjiswe, kufanele ihlolwe ngokucophelela ukuze kuncishiswe igebe endaweni ehlangene.Ngaphambi kwe-welding, izolungiswa nge-welding yendawo, bese i-welded.Iphansi le-gutter lizoshiselwa, bese kuthi uhlangothi lwe-gutter lube olushiselwe.Uma kungenzeka, ukuhlelwa kwesilingo kungenziwa, futhi ukuphakanyiswa kungenziwa ngemva kokubala izinombolo ngokuvumelana nokuhlelwa kwesilingo, ukuze kuncishiswe umsebenzi wokushisela nokuqinisekisa ikhwalithi yephrojekthi.Uma igebe likhulu kakhulu ukuthi lingashiselwa ngokugcwele ngocingo lokushisela, lingahlanganiswa ngezinto ezisele.Kudingekile ukushisela nxazonke ze-splice, futhi uqinisekise ukuthi ama-welds emaphethelweni nasemakhoneni agcwele ngaphandle kokushoda.

★ Ukufakwa kwe-gutter yepuleti yombala

1. Ukufakwa kwe-gutter yezimayini kungenziwa ngemva kokufakwa kwe-roof slab noma ngesikhathi esifanayo ne-roof slab.Imininingwane inganqunywa ngokuguquguquka ngokuya ngemibandela yesayithi.

2. Ukulungiswa kwe-gutter yepuleti yombala kuhlukaniswe izingxenye ezimbili: ingxenye eyodwa ukuthi uhlangothi lwangaphakathi lwe-gutter luxhunywe nephaneli yophahla ngezikulufa zokuzithiba noma eziboshwe ngama-rivets wokudonsa;enye ingxenye ukuthi unqenqema olugoqiwe lohlangothi olungaphandle lwe-gutter luxhunywa kuqala ngama-rivets e-gutter brace, kanti olunye uhlangothi lwe-brace luxhunywe nephaneli yophahla kanye ne-purlin ngezikulufu zokuzithinta ngokwakho ezilungisa iphaneli yophahla endaweni iphaneli yophahla.Ukuxhumana phakathi kukagutha kanye nogubhu kuvalwe ngama-rivets emigqeni emibili ngesikhala esingu-50mm ngokwezidingo ze-atlas evamile yenkampani, I-lap joint phakathi kwamapuleti kufanele ivalwe ngophawu olungathathi hlangothi.Ngesikhathi sokuhlangana kwe-lap, qaphela ukuhlanzwa kwendawo ye-lap.Ngemuva kwe-gluing, izoma isikhathi esifushane, futhi okuyinhloko kungasuswa ngemuva kokuthi i-glue ilashwe.

3. Ukuvulwa kwe-gutter outlet kungenziwa ngokuqondile ngomshini wokusika, futhi isikhundla sizohlangabezana nezidingo zokuklama.I-outlet kanye ne-gutter bottom izolungiswa ngama-pull rivets ngokuvumelana nezidingo zama-node afanelekile we-atlas evamile, futhi izidingo zokwelashwa ze-sealant ekuxhumekeni zizoxhunywa ne-gutter.

4. Izidingo zokuthi flat ze-gutter yepuleti lombala ziyefana nalezo ze-steel plate gutter.Ngenxa yokuthi kunqunywa ngokuyinhloko izinga lokufakwa kwesakhiwo esiyinhloko, ikhwalithi yokwakhiwa kwesakhiwo esikhulu kufanele iqinisekiswe ngaphambi kokufakwa kwe-gutter, ukuze kubekwe isisekelo esihle sokuthuthukiswa kwekhwalithi yokufaka i-gutter.

Isikhathi sokuthumela: Apr-03-2022