Indawo yokugcina izinto yensimbi iyisixazululo esikahle sezidingo zakho zokugcinwa nokuphatha, i-mezzanine ingamiswa njengehhovisi esitezi sesibili ukuze ihlangabezane nezidingo zehhovisi. Ivamise ukwakhiwa ngogongolo lwensimbi, ikholomu yensimbi, i-steel purline, i-bracing, i-cladding. .Ingxenye ngayinye ixhunywe ngama-welds, ama-bolts, noma ama-rivets.

Kodwa kungani ukhethe ngisho nendawo yokugcina impahla yesakhiwo sensimbi njengenketho?

I-steel warehouse vs i-traditional concrete warehouse

Umsebenzi omkhulu wendawo yokugcina impahla ukugcina impahla, ngakho-ke isikhala esanele yisona sici esibaluleke kakhulu. Indawo yokugcina impahla yensimbi inesikhala esikhulu nendawo esetshenziswayo enkulu, okuhlanganisa lesi sici. ezayo, okuyinkomba yokuthi osomabhizinisi abaningi bayayishiya imodeli yokwakhiwa kwesakhiwo sikakhonkolo esisetshenziswe iminyaka eminingi.

Uma kuqhathaniswa nezindawo zokugcina zikakhonkolo zendabuko, izindawo zokugcina izimpahla zesakhiwo sensimbi zingonga isikhathi sokwakha kanye nezindleko zabasebenzi.Ukwakhiwa kwendawo yokugcina impahla yensimbi kuyashesha, futhi impendulo yezidingo eziphuthumayo ibonakala, engahlangabezana nezidingo zesitoreji ngokuzumayo zebhizinisi.Izindleko zokwakha inqolobane yesakhiwo sensimbi yi-20% kuya ku-30% ephansi kunokwakhiwa kwempahla evamile. izindleko, futhi iphephe futhi izinzile.

Indawo yokugcina impahla yensimbi inesisindo esingasindi, Futhi uphahla nodonga kuyishidi lensimbi likathayela noma iphaneli yesangweji, elula kakhulu kunaleyo esezindongeni zikakhonkolo wezitini kanye nophahla lwe-terracotta, okunganciphisa ngempumelelo isisindo sonke sesakhiwo sensimbi ngaphandle kokuphazamisa ukuqina kwayo kwesakhiwo. .Ngesikhathi esifanayo, kungase futhi kunciphise izindleko zokuthutha zezingxenye ezakhiwe ukufuduka ngaphandle kwesayithi.

Ukuqhathanisa phakathi kweSakhiwo Sensimbi Esenziwe Ngaphambili Nesejwayelekile.

| Izakhiwo | Isakhiwo Sensimbi Esenziwe Ngaphambili | Isakhiwo Sensimbi Esivamile |

| Isisindo Sesakhiwo | Izakhiwo ezakhiwe ngaphambilini ngokwesilinganiso zilula ngo-30% ngenxa yokusetshenziswa kahle kwensimbi. Amalungu esibili ayiroli enesisindo esincane esakhiwe amalungu amise oko-“Z” noma “C”. | Amalungu ensimbi eyisisekelo akhethwa izigaba ezigoqiwe ezishisayo "T".Okungukuthi, ezigabeni eziningi zamalungu zisinda kunalokho okudingekayo ngokuklama. Amalungu esibili akhethwa ezigabeni ezijwayelekile ezigoqiwe ezishisayo ezinzima kakhulu. |

| Idizayini | Idizayini esheshayo nephumelelayo njengoba ama-PEB akhiwa ikakhulukazi izigaba ezijwayelekile kanye nomklamo wokuxhumana, isikhathi sincishiswa kakhulu. | Isakhiwo ngasinye sensimbi esivamile siklanywe kusukela ekuqaleni sinezinsiza zokuklama ezimbalwa ezitholakala kunjiniyela. |

| Isikhathi Sokwakha | Isilinganiso samaviki angu-6 kuya kwangu-8 | Isilinganiso samaviki angama-20 kuye kwangama-26 |

| Isisekelo | Idizayini elula, kulula ukwakha nesisindo esilula. | Kudingeka isisekelo esibanzi, esindayo. |

| Ukumiswa kanye Nokulula | Njengoba uxhumo lwezinhlanganisela lujwayelekile ijika lokufunda lokumiswa kwephrojekthi ngayinye elandelayo liyashesha. | Ukuxhuma kuvamise ukuba yinkimbinkimbi futhi kuyehluka kusuka kumaphrojekthi nephrojekthi okuholela ekutheni amathini andise isikhathi sokwakhiwa kwezakhiwo. |

| Isikhathi Sokumiswa Nezindleko | Inqubo yokumiswa iyashesha futhi ilula kakhulu ngesidingo esincane kakhulu semishini | Ngokuvamile, izakhiwo zensimbi ezivamile zibiza ngo-20% kune-PEB ezimweni eziningi, izindleko zokumisa nesikhathi azilinganiselwa ngokunembile. Inqubo yokumiswa ihamba kancane futhi kudingeka umsebenzi omkhulu wasensimini.Imishini enzima nayo iyadingeka. |

| I-Seismic Reistance | Amafreyimu anesisindo esiphansi avumelana nezimo anikeza ukumelana okuphezulu namandla e-seismic. | Ozimele abasindayo abaqinile abenzi kahle ezindaweni zokuzamazama komhlaba. |

| Phezu kwazo zonke Izindleko | Inani ngemitha yesikwele lingase libe phansi ngo-30 % kunesakhiwo esivamile. | Intengo ephezulu ngemitha yesikwele. |

| Izakhiwo | Idizayini yezakhiwo evelele ingafinyelelwa ngezindleko eziphansi kusetshenziswa imininingwane evamile yezakhiwo kanye nezindawo zokusebenzelana. | Idizayini yezakhiwo ezikhethekile kanye nezici kufanele kuthuthukiswe iphrojekthi ngayinye evame ukudinga ucwaningo futhi ngaleyo ndlela kubangele izindleko eziphezulu. |

| Ukwandiswa Kwekusasa | Ukwandiswa kwesikhathi esizayo kulula kakhulu futhi kulula. | Ukwandiswa kwesikhathi esizayo kuyakhathaza kakhulu futhi kubiza kakhulu. |

| Ukuphepha kanye Nesibopho | Umthombo owodwa wokuzibophezela ukhona ngoba wonke umsebenzi wenziwa umphakeli oyedwa. | Izibopho eziningi zingaholela embuzweni wokuthi ubani onesibopho lapho izingxenye zingangeni kahle, kunikezwa impahla enganele noma izingxenye zehluleka ukusebenza ikakhulukazi kusixhumi esibonakalayo somhlinzeki/usonkontileka. |

| Ukusebenza | Zonke izingxenye zicacisiwe futhi zenzelwe ngokukhethekile ukusebenza ndawonye njengohlelo lokusebenza kahle kakhulu, ukusebenza kahle kwe-fir nokusebenza okuphezulu kakhulu emkhakheni. | Izingxenye ziklanyelwe uhlelo lokusebenza oluthile emsebenzini othile.Amaphutha okuklama kanye nemininingwane ayenzeka lapho kuhlanganiswa izingxenye ezihlukahlukene ezakhiweni ezihlukile. |

Idizayini enhle kakhulu ethwala umthwalo

Umthamo wokuthwala imithwalo kufanele ucatshangelwe uma kuklanywa, ukuze kuqinisekiswe ukuthi inqolobane yensimbi ingakwazi ukumelana namanzi emvula, ingcindezi yeqhwa, umthwalo wokwakha, nomthwalo wokulungisa.Yini futhi, kumele ihlangabezane nezidingo zomthamo wokuthwala osebenzayo, amandla ezinto ezibonakalayo, ukujiya kanye nemodi yokudlulisa amandla, umthamo wokuthwala, izici ezihlukene zenguqulo, njll.

Izinkinga ezithwala imithwalo zomklamo wesakhiwo sempahla yensimbi zidinga ukucatshangelwa kahle ukuze kuncishiswe umthamo womonakalo wendawo, ukuze kuzuzwe impilo yesevisi ende.

Ukuklama ukusebenza kahle kwamandla

Uma inqolobane yendabuko kakhonkolo noma inqolobane yamapulangwe, ukukhanya kufanele kukhanyiswe imini yonke nobusuku, okungangabazeki ukuthi kuzokwenyuka ukusetshenziswa kwamandla.kodwa eyendlu yokugcina impahla yensimbi, tlapha kuzoba nesidingo sokuklama nokuhlela amaphaneli okukhanyisa ezindaweni ezithile ophahleni lwensimbi noma ukufaka ingilazi yokukhanyisa, usebenzisa ukukhanya kwemvelo lapho kungenzeka khona, nokwenza umsebenzi ongenamanzi ngesikhathi esifanayo ukuze ukwandise impilo yesevisi.

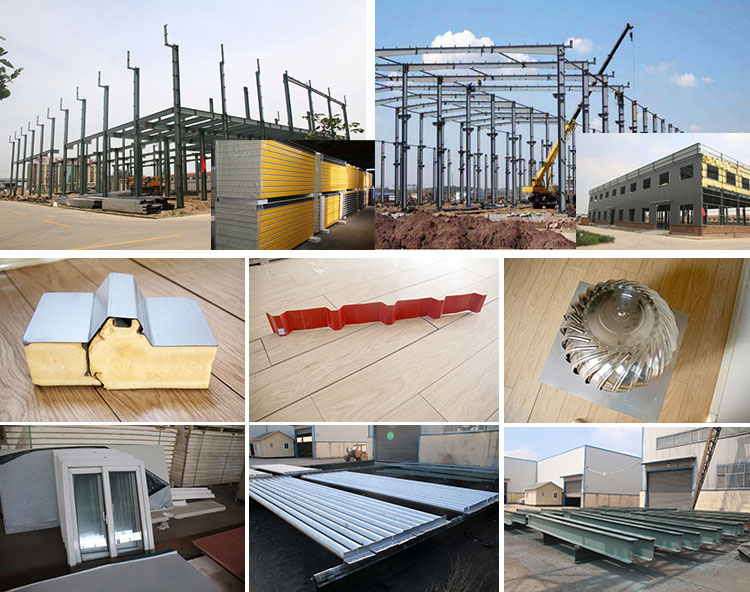

Izingxenye ezinkulu ze-PESB zihlukaniswe izinhlobo ezi-4-

Izingxenye eziyinhloko ze-PESB ziqukethe uhlaka oluyinhloko, ikholomu, namapulangwe-

Uhlaka oluyinhloko ngokuyisisekelo luhlanganisa amafreyimu ensimbi aqinile esakhiwo.Uhlaka oluqinile lwe-PESB luhlanganisa amakholomu acijile namapulanga acijile.Ama-flanges azoxhunywa kuma-webs ngokusebenzisa i-fillet weld eqhubekayo ohlangothini olulodwa.

Inhloso eyinhloko yamakholomu ukudlulisa imithwalo eqondile ezisekelweni.Ezakhiweni ezakhiwe ngaphambilini, amakholomu akhiwa izingxenye ze-I ezonga kakhulu kunezinye.Ububanzi nobubanzi buzoqhubeka bukhula kusukela phansi kuye phezulu kwekholomu.

Uhlaka lungolunye lochungechunge lwamalungu esakhiwo athambekile (imishayo) asuka enqenqemeni noma enqulwini aye odongeni, umjikelezo we-downslope noma i-eve, futhi eklanyelwe ukusekela umpheme wophahla kanye nemithwalo yawo ehambisana nawo.

I-Purlins, i-Grits kanye ne-Eave struts amalungu esakhiwo sesibili asetshenziswa njengokweseka izindonga namaphaneli ophahla.

Ama-purlin asetshenziswa ophahleni;Ama-grits asetshenziswa ezindongeni kanti ama-Eave struts asetshenziswa ezimpambanweni zodonga oluseceleni kanye nophahla.Ama-purlins nama-girts azoba izingxenye ezibandayo "Z" ezinama-flange aqinile.

I-Eve struts izoba yizigaba ze-"C" ze-flange ezingalingani.Ama-Eave angama-200 mm ukushona kanye ne-flange ephezulu engu-104 mm ububanzi, i-flange engaphansi engu-118 mm ububanzi, womabili akhiwe ngokuhambisana nomthambeka wophahla.I-flange ngayinye inodebe oluqinile olungu-24 mm.

I-cable bracing iyilungu eliyinhloko eliqinisekisa ukuzinza kwesakhiwo ngokumelene namandla ekuqondeni kwe-longitudinal njengomoya, ama-cranes, nokuzamazama komhlaba.Kuzosetshenziswa i-diagonal bracing ophahleni nasezindongeni eziseceleni.

Amashidi asetshenziswa ekwakhiweni kwezakhiwo ezakhiwe ngaphambilini ayinsimbi eyisisekelo yensimbi evalwe nge-Galvalume evumelana ne-ASTM A 792 M grade 345B noma i-aluminium evumelana ne-ASTM B 209M eyinsimbi egoqekayo ebandayo, ingcindezi ephezulu engu-550 MPA, eshisayo. cwilisa i-metallic coating ye-Galvalume sheet.

Izingxenye zezakhiwo ezingezona ezakhiwe njengamabhawudi, ama-turbo ventilator, ama-skylights, izithandwa, iminyango namafasitela, ama-curbs ophahleni kanye nezinsimbi zenza izingxenye zezesekeli zesakhiwo sensimbi esakhiwe ngaphambili.

Ukufakwa

Sizohlinzeka amakhasimende ngemidwebo yokufaka namavidiyo.Uma kunesidingo, singathumela onjiniyela ukuze baqondise ukufakwa.Futhi, ilungele ukuphendula imibuzo ehlobene yamakhasimende noma kunini.

Esikhathini esidlule, ithimba lethu lezokwakha liye emazweni amaningi nasezifundeni ukuze lifeze ukufakwa kwendawo yokugcina impahla, indawo yokusebenzela yensimbi, imboni yezimboni, indawo yombukiso, ibhilidi lehhovisi nokunye.Isipiliyoni esicebile sizosiza amakhasimende onge imali eningi nesikhathi.